Image 1 of 6

Image 1 of 6

Image 2 of 6

Image 2 of 6

Image 3 of 6

Image 3 of 6

Image 4 of 6

Image 4 of 6

Image 5 of 6

Image 5 of 6

Image 6 of 6

Image 6 of 6

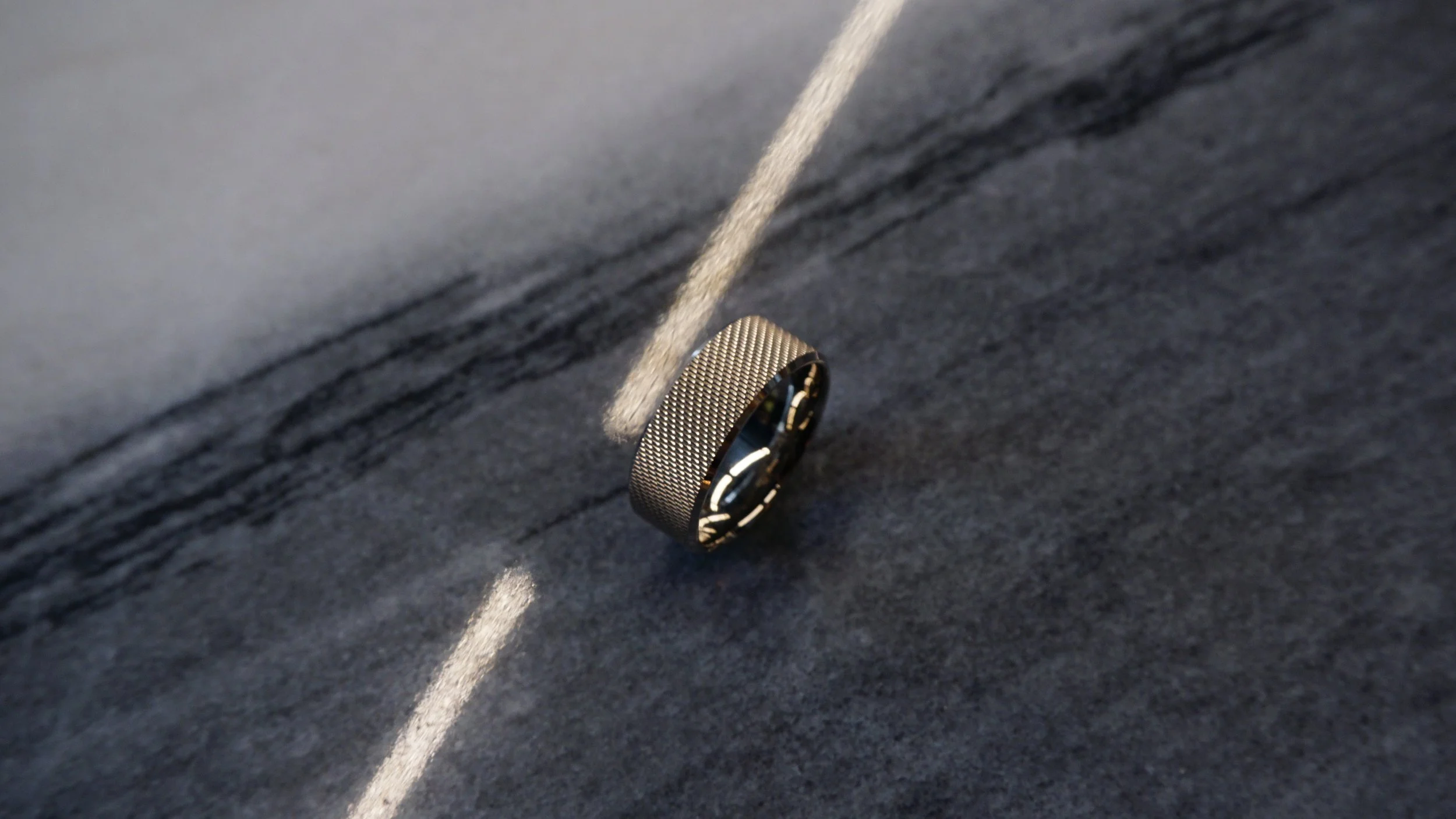

The Implication

Think high end audio equipment dials and knobs.

This intricate diamond pattern is embedded into the metal through a process known as knurling.

A special tool is rolled around the ring repetitively, slowly imprinting the pattern into the surface of the metal.

The shimmer of this finish is extremely difficult to capture on camera. You’ll notice it appears lighter or darker depending on the angle of the photos.

The ring also features finely chamfered and polished edges, highlighting the knurling through the centre.

It can currently be made in any precious metal.

The pictured variant is 18ct palladium white gold with no rhodium plating.

The standard width is 6mm and the standard thickness is 1.6mm.

Your width and finger size can be confirmed upon receiving our 3D printed sizing kit.

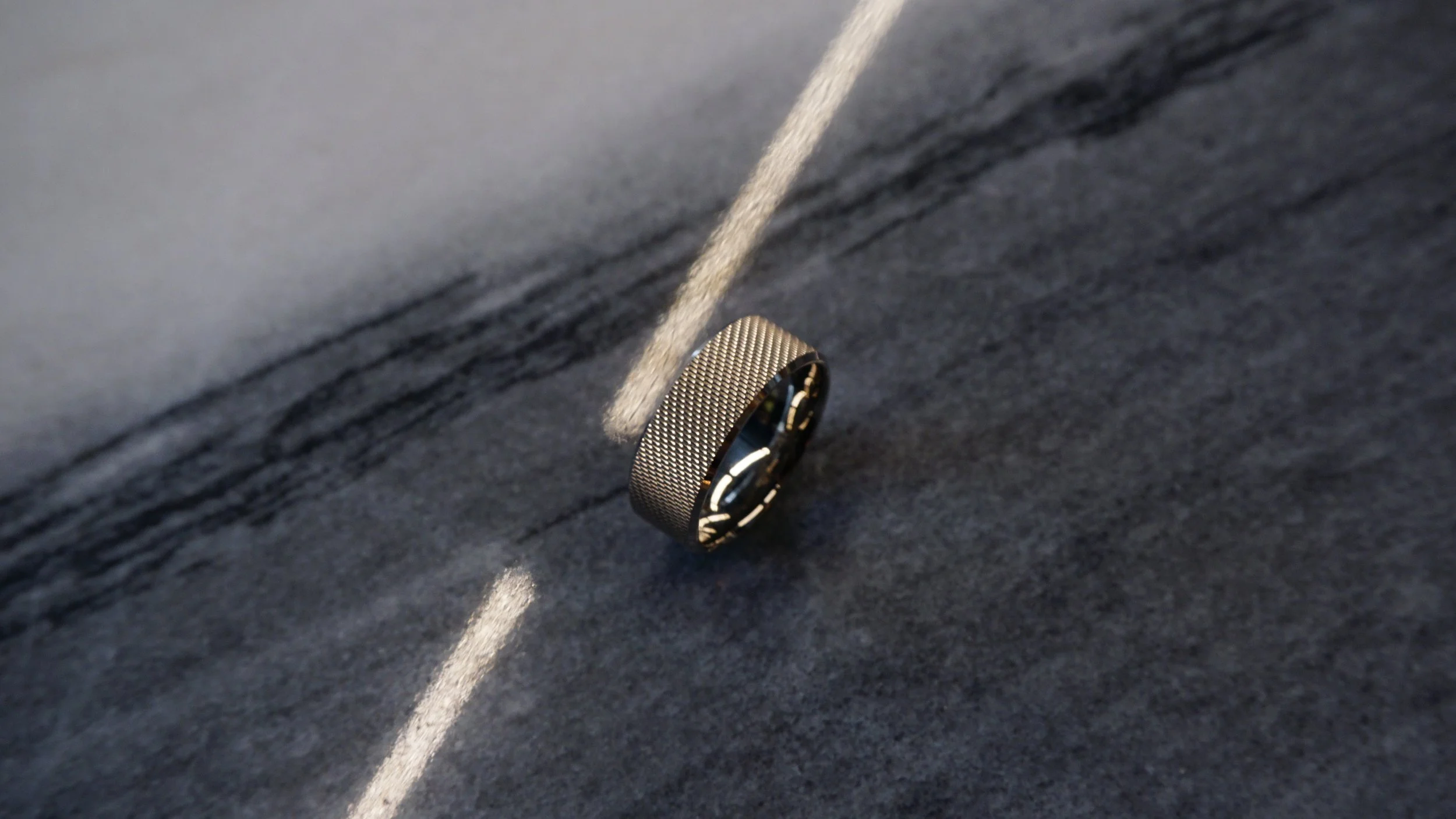

Think high end audio equipment dials and knobs.

This intricate diamond pattern is embedded into the metal through a process known as knurling.

A special tool is rolled around the ring repetitively, slowly imprinting the pattern into the surface of the metal.

The shimmer of this finish is extremely difficult to capture on camera. You’ll notice it appears lighter or darker depending on the angle of the photos.

The ring also features finely chamfered and polished edges, highlighting the knurling through the centre.

It can currently be made in any precious metal.

The pictured variant is 18ct palladium white gold with no rhodium plating.

The standard width is 6mm and the standard thickness is 1.6mm.

Your width and finger size can be confirmed upon receiving our 3D printed sizing kit.

How long does it take to make?

4 weeks is our standard lead time. Titanium and zirconium rings can be faster. Let us know during checkout when you need your ring, and we’ll aim to meet your deadline.

Getting the width right.

Choosing the most appropriate width for your hand online is near impossible. That’s why we’ll send you a 3D printed set of width options ranging from 4-8mm. Confirm your width before we begin production. Depending on the chosen ring, this may increase or decrease the price. We’ll confirm with you first.

What if I don’t like it?

If you don’t like your ring (unlikely), we’ll give you a full refund or exchange for another design, even though they are custom made to order.

What if it doesn’t fit right?

You’re entitled to one free resize, sometimes this requires a complete remake of the ring, which is also included.

Packaging

All rings come with our in-house designed, machined billet aluminium ring case.

A quality ring deserves a quality case. No wood or paper here.

3D Printed Sizing Rings Included.

Our 3D printed sizing rings allow you to find your size in the convenience of your home and come included with all orders.

In fact we find this process more accurate than going to a store to be sized. You get the opportunity to try the sizes in the specific width of the ring ordered, and over a longer span of time.